Applied Standard:

JIS Q 9100:2016 & JIS Q 9001:2015 (ISO 9001:2015)

Scope of Certification:

Production of sheet metal parts for Airplane

Interiors

Non Applicable Clause(s)

8.3 Design and Development of Products and Services

Scope Categories

17 Basic metals and fabricated metal products

21 Aerospace

Certified Site Name, Location, and Scope of Certification

Applied to th e Site (Product/Service, Process, etc.):

1.Stainless Art Kyoei Co., Ltd.

3767 15 shimonanbata, Fujimi shi, Saitama ken

354 0004 JAPAN

Same as Scope of Certification

Service

Designing and analyzing/ Precision sheet metal/ Welding/ Polishing / Machining/ Assemling/ Manufacturing various jigs/ Prototyping and development

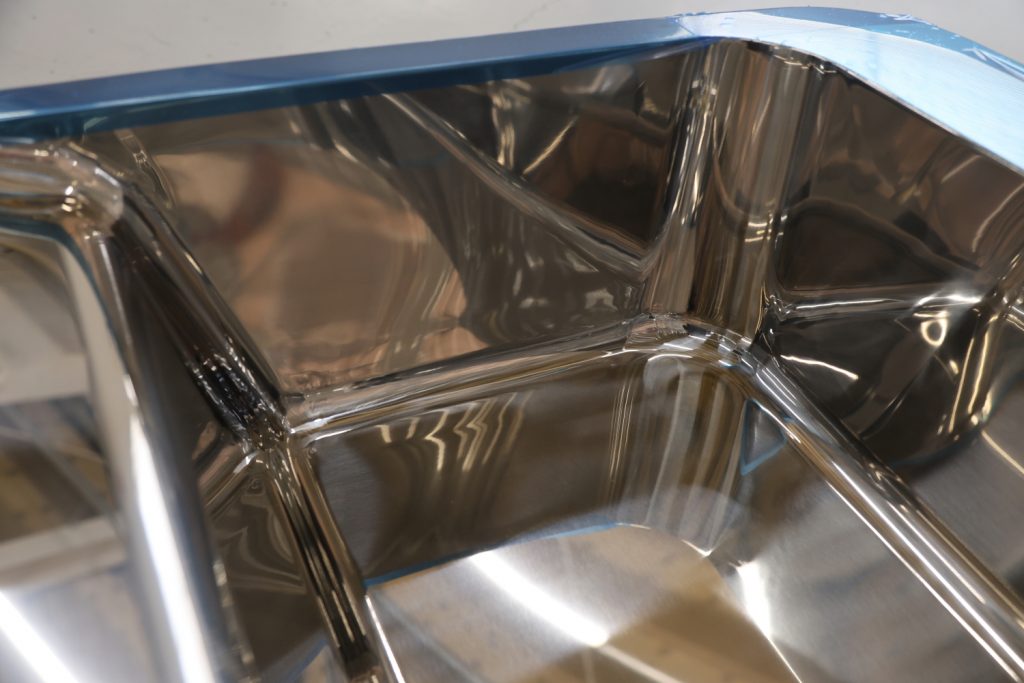

Stainless Art Kyoei manufactures items to make functional and artistic values coexist by combining polishing technique that makes metal surface extremely flat and special welding technique that prevents metal from distorting.

Besides, the company improved the precision and speed of manufcturing by fully introducing 3D CAD.

Furthermore, we employe a flexible production system that enables not only supplying a palm-sized prototype and designing a full size mechanical equipment but also assembling it on a one-stop basis.

Another strength is our ability to understand and interpret client’s dream and intent by hearing its rough image and priority, and to embody them without design drawings .

Precision sheet metal

By combining our core technology of thin plate welding and polishing, we have achieved many R-bent workings, which are not nomally taken up by regular sheet metal working .

Stainless Art Kyoei is good at precision sheet metal working for many kinds with a small to medium quantity.We are ready to propose our manufacturing work that transforms your concept and imagination to a concrete shape.

Welding

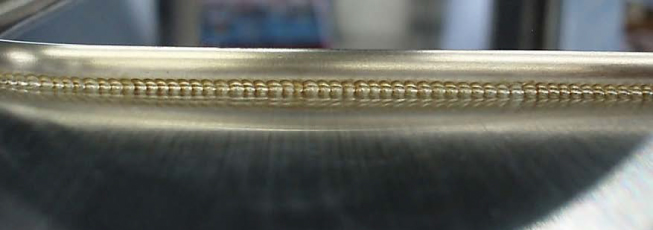

Founded as a polishing company as a background, we pursue aesthetic welding by imagining how to polish and finish after welding.

Polishing

It is never an overstatement that client’s judgement of a product depends on polishing finish provided to the appearance of the product.

Our clients range from food industry and medical fields where strict sanitary complience should be met, to building materials industry and interior/exterior fields etc.

Our polishing skills range from hairlines, vibration, #400 and #800 up to design polishings.

Designing and analyzing

We have the facilities and ability to do 3D desining and structural analysis so that a consistent care of “initial design through final product” can be taken.

In recent cases where we provided mechanical equipment in the medical field and in the food industry respectively, Stainless Art Kyoei got involved in the projects from the initial desining stage, proceeded through value adding processes together with the individual clients, and delivered only-one-in-the-world product to the respective clents.

Assemling

As such, we have the capacity and ability to receive an entire project from designing, analyzing and sheet metal working through painting and assembling consistently.

Knowing our potential, our products base is continuously expanding from medical and food mechanical equipment to digital signage, ticketing machines, hardware of theme parks, interior items, prototype development of amusement devices and so forth. We will be delighted to explore any new field of opportunities where we will be able to further evolve our skills and technology.